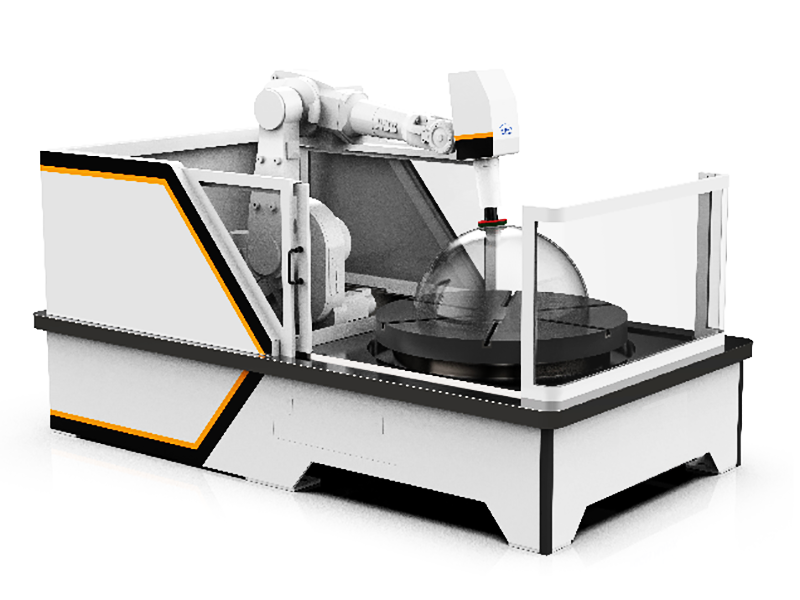

Robot grinding and polishing machine

A small tool machining machine tool based on industrial robots utilizes small tools to rotate at high speed on the surface of components, achieving rapid convergence of the surface shapes of planar, spherical, and aspheric components.

By utilizing a self-developed flexible polishing head based on force controlled sensors, the material removal function during the polishing process is ensured to be stable and controllable, thus achieving high-precision machining of the surface of ultra precision components. In conjunction with full chain processes and software, the full chain machining of optical components from grinding to precision polishing is achieved.

Applications

High precision machining of the surface of ultra precision components, combined with full link processes and software, achieves full link processing of optical components from grinding to precision polishing.

Features

1. Based on a dedicated control system for industrial robots, high-precision surface forming is achieved.

2. The design of a flexible polishing head based on force controlled sensors accurately controls the removal function of the machining process.

3. According to the processing requirements, open full link processing software development.

4. Customized development according to customer requirements