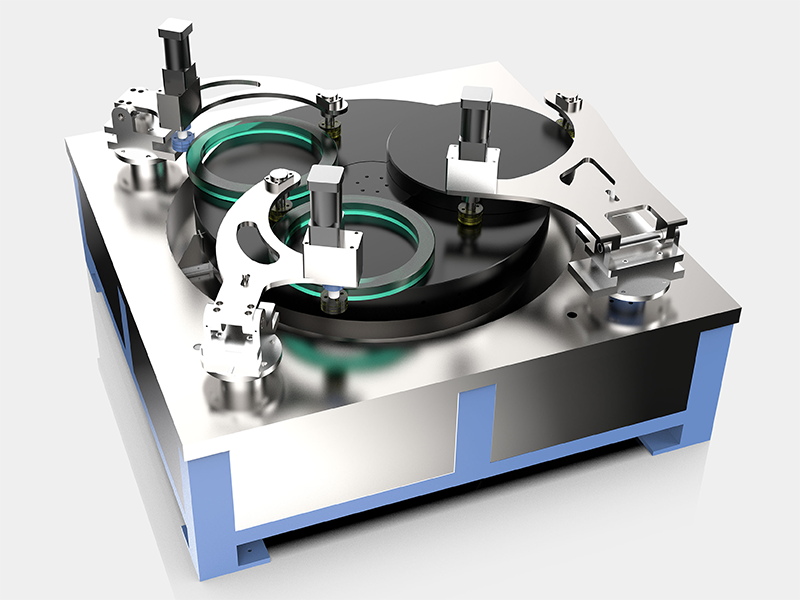

Full aperture intelligent ring polishing machine

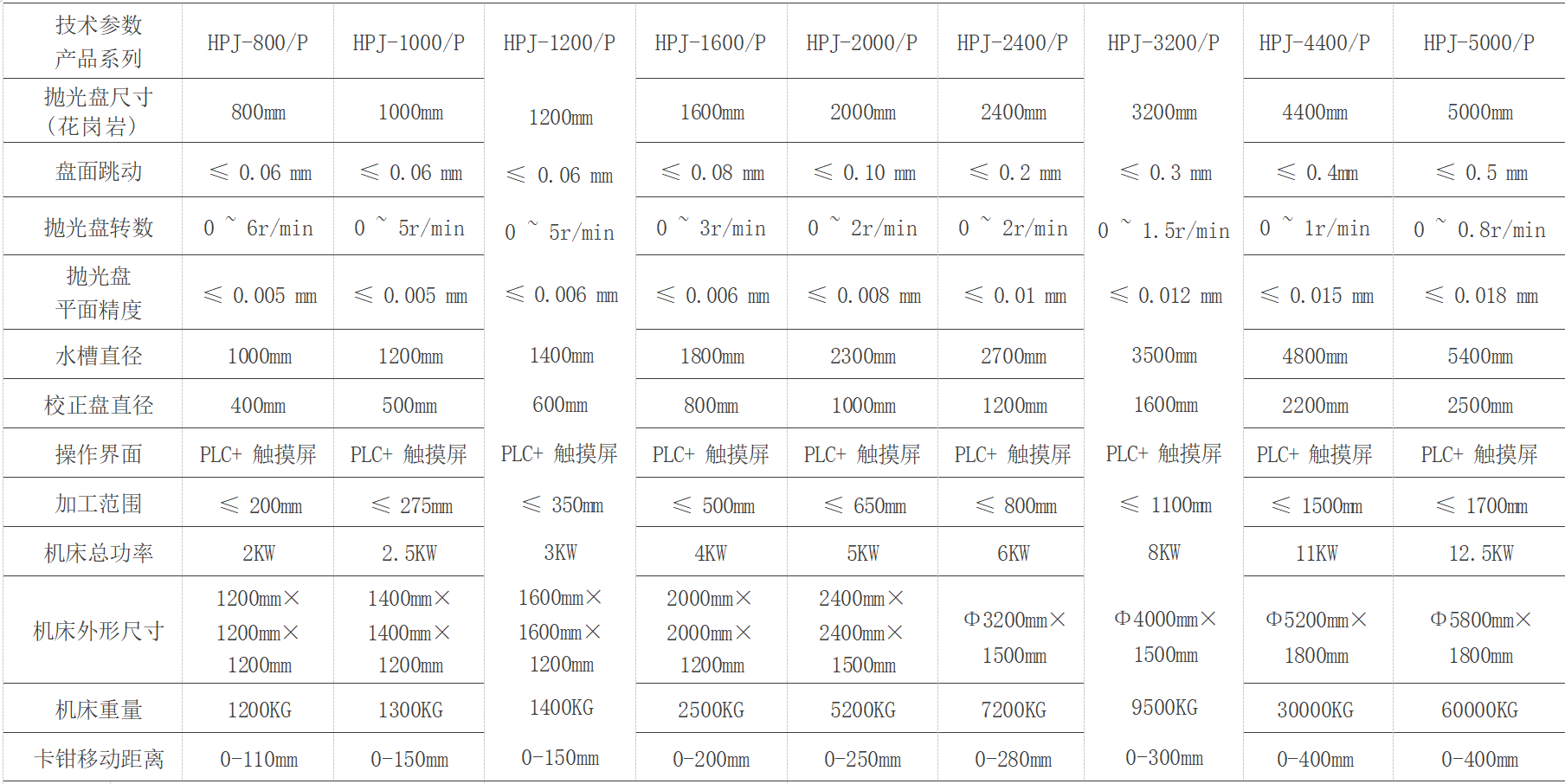

Provide various specifications of circular polishing machines with automatic monitoring and control functions for full process parameters such as rotational speed, eccentricity, and unloading of correction plates, used for high-precision and ultra-high-precision flat mirror processing.

Applications

Used for the processing of high-precision and ultra-high-precision flat mirrors.

Features

1. Full caliber intelligent ring polishing machine, using high flatness marble and high-precision turntable bearings; The spindle adopts a servo motor with constant torque output; Adopting PLC+touch screen control.

2. Integrate process parameter monitoring and surface shape online monitoring through automated programs, and achieve real-time collection of process parameters.

3. Provide full process chain technical support for ring polishing, such as polishing glue, automatic liquid injection, and automatic slotting, and can provide sample trial production.

4. Customization can be developed according to customer requirements.