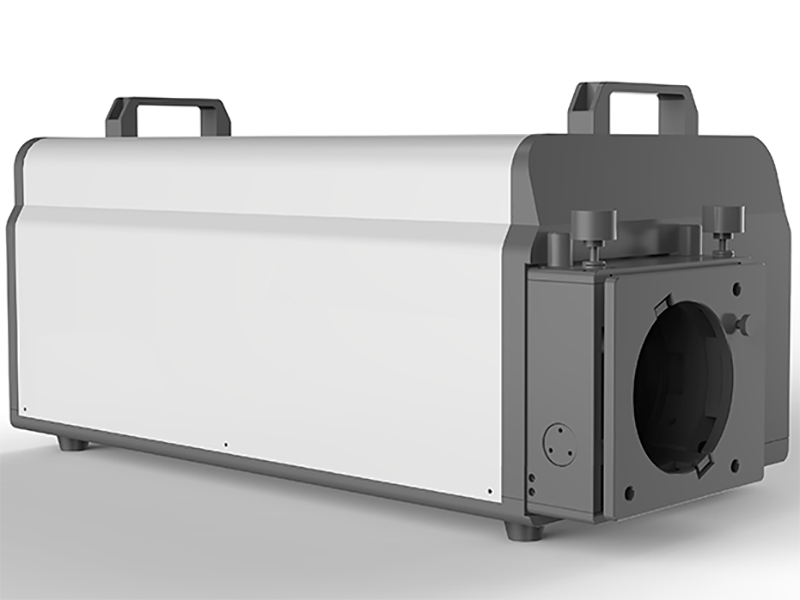

4 hour laser interferometer

Laser interferometers use phase shifting technology to accurately characterize the three-dimensional morphology of the measured surface, with measurement accuracy of up to 0.06um or even higher, and are widely used for high-precision detection of planar optical components.

Applications

Widely used for high-precision detection of planar optical components.

Features

1. Accurately measure the transmitted and reflected wavefront of optical components with a diameter of 100mm or less.

2. The measurement accuracy and repeatability are comparable to the American Zygo and 4D interferometers.

3. Customized development according to customer requirements.

-

Technical Data

Items

Ty

Testing Method

Fischer interference principle

Phase shifting method

Wavelength phase shifting or mechanical phase shifting

Host wavelength

632.8nm (can be customized)

Main camera resolution

2048*2048

Measuring caliber Main camera focusing ability

Main camera acquisition speed

50Hz

Transmission plane reference mirror shape error

Poor (PV)

λ/10

Reflection plane reference mirror shape error

Poor (PV)

≦ λ/10(can be customized to λ/20)

Cavity accuracy (PV)

≦ λ/10, λ=632.8nm

Repeatability of surface error measurement

(RMS)

≦ 1nm (2δ)

Measuring high parallelism optical elements

Transmission and reflection wavefront

Support

Standard accessories

Computer, stripe monitoring and analysis software

Coherence length

1.0m (if beam is expanded, this parameter will become longe)

Operating temperature requirements

22℃ ±1℃

Working temperature fluctuation requirements

Less than 1 ℃ change per hour

Working humidity requirements

55%±10%RH

isolation requirements

Air floating platform, natural frequency: 1-2Hz

working voltage

AC 110-220V,50/60Hz